Introduction

Orphys Production Line and Shipping Schedule Optimator (Orphys PLSSO) is a program cluster made to help management team in a company to manage, how customer's demand is fulfilled, using any available company's resources, in the least costly way.

Orphys PLSSO is capable to automate and optimalize the production and shipping schedule for manufacturing companies with multiple factory and multiple warehouse. As the program cluster it is capable of trying different possible schedule based on some heuristic value in a short time, and tell the production management team the least costly schedule found.

Assumption

In order to do its task, the program make several assumption about the company :

- the company have one or more factories.

- the company have one or more warehouses.

- the company may have one or more production lines in a factory.

- the company have more than one means to transport their product to customer.

- each factory have a storage area for finished product, which are warehouse in their own sense.

Several assumption about the production lines :

- raw materials inputed into a production line, will yield finished products.

- a production line may consist of several machine and tools.

- a production line can't use other production line's resources (machine or tools).

- production lines will have some lag time, if asked to produce a product it is not currently producing (setting time).

And several other assumption about the company's customer :

- customers want to get their ordered product on time.

- customers will give the company a deadline, to produce and ship their product.

- customers may be located in different geographic area (cities, state, country).

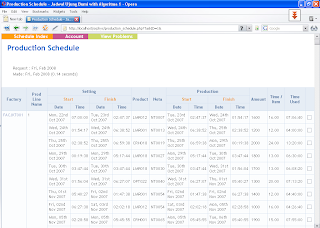

Production Schedule, tells company management teams, at what time a production line must :

- start producing product A. ( production )

- change the production line's setting to produce product B. ( setting )

- start producing product B. ( production )

- change the production line's setting to produce product C. ( setting )

- and so on.

Overtime Schedule, tells company management teams, in which day and how long a production line must work outside normal workhour (overtime). This feature can be disabled if the company policy don't allow overtime.

Inter-Warehouse Shipping Schedule, tells company management teams, when a finished product must be moved from a factory to a warehouse, or must be moved between warehouses.

To-Customer Shipping Schedule, tells company management teams :

- when a finished product must be shipped to customer.

- which shipping or transportation method must be used ( truck, ship or airplane, for example).

- how much shipping days is needed.

- when customer will recieve the shipped product.

Transport Cost Detail, is a detailed report about how demand on a set of product, is fulfilled by the production and shipping schedule generated by Orphys PLSSO. The report also tells the cost required to ship a customer's set of ordered product.

Estimated Cost, is a short report about the estimated cost involved, if the current plan is executed. The calculated costs are :

- Inter-warehouse Shipping Cost ( Per Warehouse ).

- To-Customer Shipping Cost ( Per Warehouse ).

- Production Lines Salaries ( Per Factory ).

Download an Example of Orphys PLSSO Schedule. ( HTML )

Learn More about Orphys :

Orphys PLSSO Program ClusterOrphys Production Line and Shipping Schedule Optimator (Orphys PLSSO) is a program cluster made to help management team in a company to manage, how customer's demand is fulfilled, using any available company's resources, in the least costly way.

Orphys PLSSO is capable to automate and optimalize the production and shipping schedule for manufacturing companies with multiple factory and multiple warehouse. As the program cluster it is capable of trying different possible schedule based on some heuristic value in a short time, and tell the production management team the least costly schedule found.

Orphys PLSSO is not a single program, it is a system consisting of several programs, They are :

- Orphys Optimalization and Learning Server (OOLS)

- Orphys Input Module

- Orphys Web-based Interface

Orphys Optimalization and Learning Server (OOLS), is the brain of Oprhys PLSSO system. For Orphys PLSSO System to work, this OOLS program must simply be activated. When a company want to use Oprhys PLSSO system to optimize their production and shipping schedule, Orphys Web-based Interface will tell OOLS to make a schedule. When there is no request for any optimation, OOLS will learn from previous cases, about how to optimally optimize the company's production and shipping schedule.

Orphys Input Module, is one of two interface by which end-user can request OOLS to make and optimize a company's schedule. Orphys Input Module will ask end-users some information about the company, and turn the information into five files ( *.fac ; *.nmf ; *.fwhc ; *.ord ; *.nona ), which must be inputted later into Orphys Web-based Interface to make a schedule.

Orphys Web-based Interface, is the other interface by which end-user can request OOLS to make and optimize a company's schedule, by inputting the five files ( *.fac ; *.nmf ; *.fwhc ; *.ord ; *.nona ) generated by Orphys Input Module. This Web-based Interface is also useful for viewing the created schedule and report.

Download an Example of Orphys PLSSO Schedule. ( HTML )Learn More about Orphys :

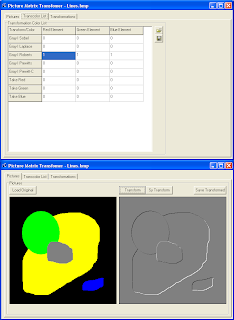

Orphys Input ModuleOrphys Input Module is a program, created as an interface for an end-user, to enter the information about company's resources and customer's order, that must be scheduled properly to avoid high fulfillment cost.

There are several information that must be provided for Orphys PLSSO to make a optimized schedule, they are :

Environment Configuration- Number of City and names of the Cities

- Number of Shipping Service available, and their names

- Shipping Service Cost and Time Matrix

Product Configuration- Machinery and Tools required to make a product

- Data of Product and the Production Line Setting required to make a product

Customer and Ordering- Customer Data

- Port To Customer Cost Matrix

- Nota and Nota Detail Information

Factory Configuration- Number of Factories and Basic Factory Data

- Initial Production Line Configuration

Warehouse Configuration- Current Warehouse Configuration Data

- Warehouse To Shipper Cost Matrix

- Warehouse's Finished Product Stock Matrix

Notice, that most page have a save and load buttons. These buttons are used to save or load some parts of the company information for later use. After saving some parts of company information, end-users can load the saved information by using load buttons, without the need of rewriting the information from scratch.

To convert the information into five files ( *.fac ; *.nmf ; *.fwhc ; *.ord ; *.nona ), which is required for

OOLS to make and optimize a schedule, open the conversion page, and click write button. Conversely you can also read company's information from five file format, by clicking read button in conversion page.

Download an Example of Orphys PLSSO Schedule. ( HTML )Learn More about Orphys :

About OrphysOrphys Production Line and Shipping Schedule Optimation, is a program I made to help manufacturing companies schedule their production and product shipping. The

assumption had already been listed above.

If any reader here is interested to implement Orphys PLSSO in their company, just contact me by email.